When the excavation had been completed and made safe, the construction of the waterproof concrete basement with aesthetic facing concrete began.

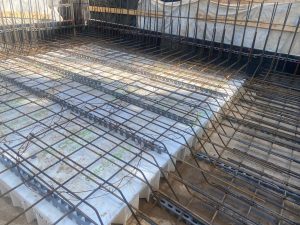

Main slab & insulation

Prior to pouring the concrete, a layer of insulation was placed on the ground to prevent heat loss and moisture infiltration. This insulation not only enhances energy efficiency but also provides a barrier against cold temperatures, crucial for maintaining a comfortable and dry basement environment. Once the insulation is laid, the two sumps (foul and ground water) are installed and steel reinforcement bars were positioned to reinforce the concrete slab, ensuring structural integrity, and preventing cracking. Finally, the waterproof concrete was cast and levelled. As the concrete cures, it forms a solid and durable foundation for the basement space, offering stability and insulation against external elements as well as the primary defence from water ingress.

Basement walls

Casting waterproof concrete basement walls with expanding waterbar involves meticulous attention to detail to create a resilient barrier against water intrusion. Before pouring the waterproof concrete, the slab kicker is treated with a cementitious waterproofing slurry and an expanding waterbar was placed within the forms to provide additional waterproofing protection. These waterbars are designed to expand when exposed to moisture, effectively sealing any potential gaps or cracks that may develop over time. Steel reinforcement is carefully integrated into the waterproof concrete structure to provide strength and durability and reduce cracking. Throughout the casting process, measures are taken to ensure proper compaction and curing, minimising the risk of cracks, and improving the overall integrity of the walls.